Chapter 3: Galvanized Pipe Fittings/PVC fittings¶

Previously, Lead pipes was the common choice to transport water. As a solution to lead poisoning, builders began to use galvanized steel pipes and fitting alternative to lead. Steel pipes are dipped into molten zinc for galvanization. This zinc coating prevents pipe from corrosion and rust. Galvanized pipes are beneficial because of its cheaper price than copper and more durable than plastic. Also, it has wider diameter to allow more water through compared to copper. Its drawback is the internal corrosion that builds up along the interior of the pipe over time due to reaction of minerals in the water, with zinc.

Similarly, PVC stands for polyvinyl chloride and it has become a common replacement for metal piping. It’s a white plastic pipe commonly used for plumbing and drainage. PVC fittings are beneficial because of its strength, durability, easy installation and low cost.

A fitting is a connector that connects straight pipe or tubing sections, adapt to different sizes or shapes for various purposes.

Figure 3-1. a) GI pipe and fitting b) PVC pipe and fitting¶

G.I pipe nipples¶

A nipple is a fitting, with short piece of pipe with outer surface thread (or male pipe thread) on both ends for connecting other two fittings. A nipple with continuous uninterrupted threading is called close nipple and is unscrewed by nipple wrench while normal nipple can be unscrewed by pipe wrench. And other types of nipples are illustrated in given figure.

Figure 3-2. G.I pipe nipples¶

G.I elbows¶

The pipe is bent to form an elbow. There are issues with bends since the thickness at the bend radius reduces as we bend the pipe. Sharp bends normally called elbows. Bends usually have a minimum bending radius of 1.5 times pipe radius (R). If this bending radius is less than 1.5R, it is called elbow. The most common bending radii in the industry are 1.5R, 3R and 4.5R.

An elbow is used in a pipe supply to change the direction of pipe usually a 90° or 45° angle. When two ends of elbow has different size then it is known as a reducing elbow.

Figure 3-3. G.I elbows¶

G.I tee¶

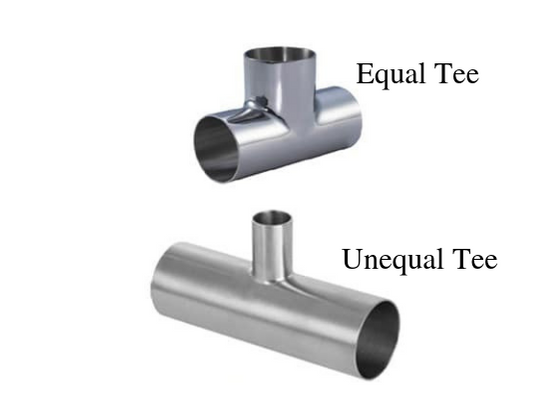

It is a component of plumbing system with one inlet and two outlets arranged at 90° which is in T shape. It can be use to divide flow of one main inlet into two outlets or combine two inlet flows into single outlet. If all the three sides of Tee-fitting has same size then it is called equal tee otherwise it is called unequal tee.

Figure 3-4. G.I tee¶

G.I cross¶

GI cross fitting contains 4 opening in 4 directions. These types of fitting generates more stress on pipe as the temperature changes, because they are located at center point of four connections.

Figure 3-5. G.I cross¶

G.I reducing elbow¶

A reducer is used to change the pipe size to meet hydraulic flow requirement of the system. With the help of reducing elbow you can increase or decrease the flow of water supply in water supply system.

Figure 3-6. G.I reducing elbow¶

G.I sockets¶

G.I sockets is a fitting, with short piece of pipe with inner surface thread (or female pipe thread) on both ends for connecting other two fittings. The opening of sockets matches the outer diameter of a pipe or tube which are to be connected.

Figure 3-7. G.I sockets¶

G.I reducing sockets¶

G.I reducing sockets is a socket which reduces the flow size from larger to smaller or vice-versa.

Figure 3-8. G.I reducing sockets¶

G.I plugs and caps¶

A Plug is a plumbing component which is used to close pipe opening during inspection and repairs. Plugs with male threads are generally available.

A Cap is a type of pipe fitting which works similar to plug i.e. to close the pipe, but it has female threads instead of male threads. It can be available in different materials like rubber, copper, steel, plastics etc.

Figure 3-9. G.I plugs and caps¶

Flange unions (Gasket) (review needed)¶

A coupling is used to connect the pipes of same diameter. It is useful if the pipe is broken or leakage occurs. There are two types of coupling available- slip coupling and compression coupling. Slip coupling fix long length damage pipes while compression coupling is regular coupling.

A union is a type of fitting which also connects two pipes, but we can disconnect union of two pipes whenever we need. It consists of nut, male and female ended threads.

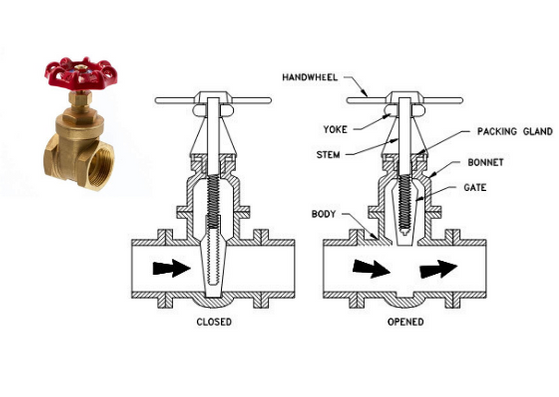

G.I gate valve (heavy and light)¶

Valves are components of plumbing system which stops or regulates the flow of liquid or gas in its path. Different types of valves are available according to their applications like gate vale, glove valve, check valve, diaphragm valve, butterfly valve, ball valve, foot valve etc.

Gate valve is normally used for isolation application where fully close or fully open position is required. This kind of valves are best suited for place where frequent opening and closing is done.

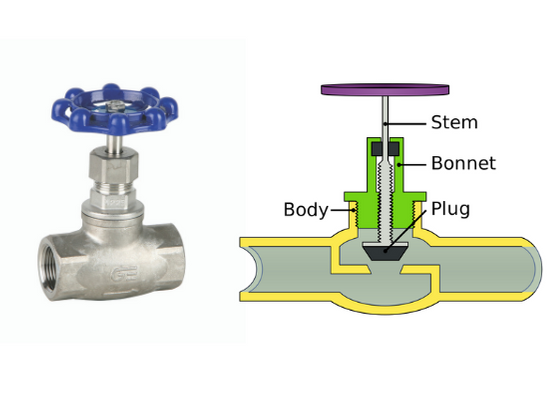

Foot valve/Glove valve¶

Glove valve is used in high pressure stream and water line. It can be used for throttling purpose and where shutoff is required. Also, it can be employed in isolation and regulation jobs.

Foot valve are used to prime up the centrifugal pump which helps to maintain hydraulic pressure to keep the water flow in accordance with the given configurations. It is made of PVC plastic or stainless steel.

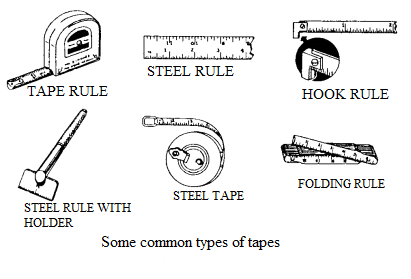

Pipe tape¶

Given figure illustrates some of the commonly used pipe tapes. Steel or wooden straightedge is the most common and simplest measuring tool. This rule is usually 6 or 12 inches long. The thinner the rule is, the easier it is to measure accurately with it, because the division marks are closer to the work to be measured.

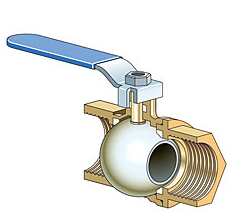

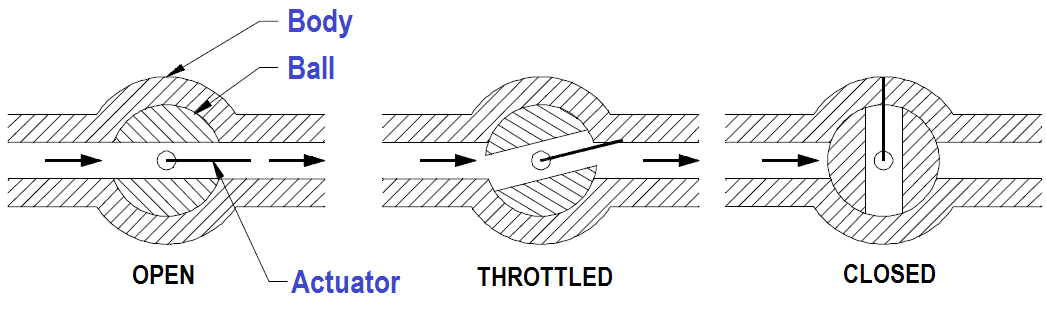

Float valve or ball valve¶

A ball valve is one type of quarter turn valve which have a ball placed in a passageway through which fluid flows. The ball has a hole through it by which valve is opened and closed. To pass the fluid in same direction, ball must be positioned as the passageway. When the ball is positioned as hole is perpendicular to the passageway then valve is closed, and fluid cannot pass through.